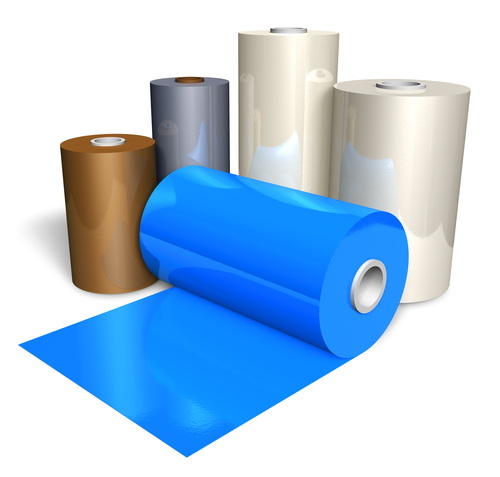

Engineered Films

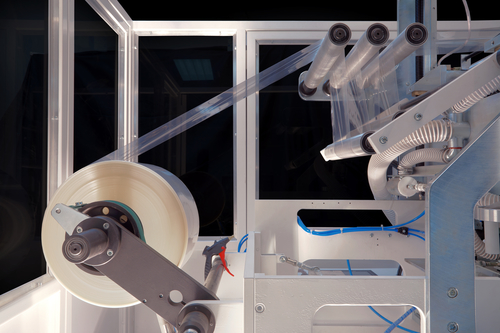

Our team are experts in the field of polymer extrusion technology. Hands-on experience in the development and direct manufacture of films for multiple applications gives us the knowledge to engineer a film that performs to your requirements. Utilizing blown and cast extrusion, as well as laminating, allows for the flexibility needed to develop films for many applications. Our experience has led to advancements in films demanding extremely high levels of performance. Whether your application requires a monolayer, coextrusion or lamination, we can design a film that meets your needs.

Polymer Films

Monolayer Films

Monolayer films are among the most widely used in the packaging industry. We offer a variety of these cost effective and versatile films for many suitable applications. These films are formulated with other resins and concentrated additive packages to achieve intended performance characteristics. All materials are designed by our team with the input provided by our customers.

Materials

- LDPE

- LLDPE

- HDPE

- Metallocene

Applications

- Machine grade conversion films

- Shrink films

- Horizontal(HFFS) and vertical(VFFS) form/fill/ seal

Coextrusion

Coextrusion, available in blown or cast, is manufactured by the use of multiple extruders to deliver a flow of multiple specified polymers to a single die creating a single film with multiple layers. Each layer is designed with specific performance characteristics. Our principal ownership group has been actively involved in the direct manufacture of coextrusion since 1985. When a monolayer film cannot meet the demands of an application we can design a coextruded film to address those challenges.

Materials

- LDPE

- LLDPE

- HDPE

- Metallocene

- Polypropylene

- Nylon

- EVOH

- EVA

Applications

- Machine grade conversion films

- Barrier films

- Horizontal(HFFS) and vertical(VFFS) form/fill/ seal

- Forming and non forming films

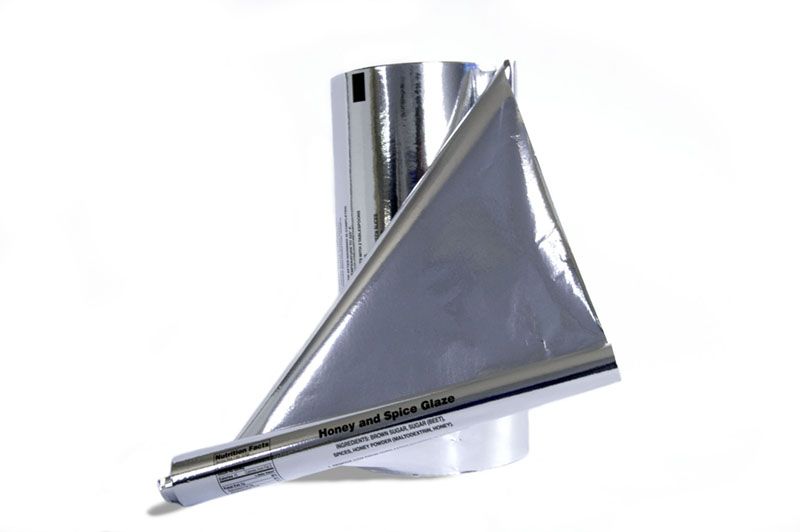

Laminations

Laminated structures are used to further improve barrier properties of a substrate as well as improve the aesthetic appeal of packaging materials for retail use. Laminated films use multiple substrates and are adhesive bonded together and can be coated or printed. These structures are used to produce pouches, stand-up pouches and form/fill/seal films to keep your packaged product fresh from oxygen and water vapor transmission and to block odors from penetrating the package either from the inside out, such as coffee, or the outside in. We offer a wide variety of laminated substrates each designed with specific performance characteristics to meet your needs.

Materials

- LDPE

- LLDPE

- HDPE

- Polypropylene

- Nylon

- EVOH

- PET

- Metalized PET

- OPP

- Metalized OPP

- Matte OPP

- Foil

- Paper

Applications

- Machine grade conversion films

- Barrier films

- Horizontal(HFFS) and vertical(VFFS) form/fill/ seal

- Static shielding